Wielding a shiny chrome scoop, Michael Rosenthal leans over and digs into the powder in a half-filled 55-gallon drum. He holds up the news and takes a pinch in his fingers and smooshes it to point out me the feel. It’s like talc, however it’s an odd, stunning shade of pale green-gray. On cabinets throughout us are big white baggage of the stuff, every weighing a metric ton.

The truth that this explicit powder exists in any respect is principally a miracle. That’s the inescapable conclusion for me at this level after a kind of impromptu, peripatetic mini-seminar carried out by Rosenthal right here in

Mountain Pass, Calif., close to the Nevada border. Rosenthal is cofounder and chief working officer of MP Materials, the one firm in North America that’s mining uncommon earth ore and—that is the vital half—extracting from it massive portions of industrially helpful rare earth compounds.

The powder he’s exhibiting me is a mix of pure

rare earth oxides, principally neodymium with some praseodymium. It’s the important thing ingredient in numerous crucial processes and merchandise in semiconductor manufacturing, electro-optical methods, chemical catalysis, and, most notably, highly effective everlasting magnets. These are the magnets that go into almost all motors for electric vehicles and into climate-control methods, home equipment, and instruments, into the mills utilized in wind generators, and into the tons of of hundreds of thousands of headphones and loudspeakers offered annually.

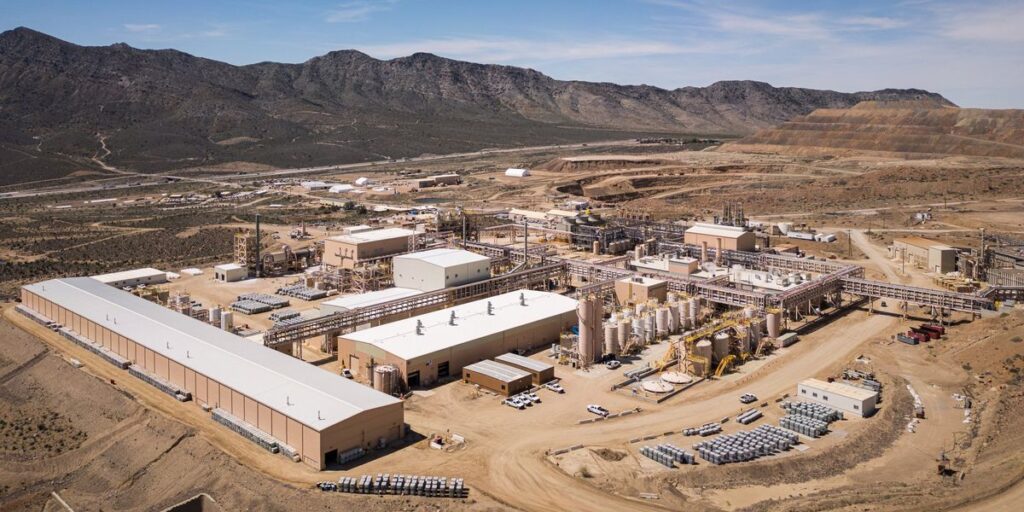

For the previous couple of hours, because the temperature climbed towards 43 °C (110 °F), I’ve been traipsing with Rosenthal round

MP’s open-pit mine and sprawling processing amenities within the northeastern Mojave Desert. Earlier, as we stood on the sting of the huge mine pit, Rosenthal identified within the partitions of sunshine grayish “nation rock” far beneath us the seams of brownish and reddish rock, which include the uncommon earth ores. “There’s been uncommon earth mining right here since 1952,” he stated. “We predict we’ve acquired no less than one other 30 years to go.”

That’s a comforting thought to authorities officers and tech executives in Europe, North America, Japan, and Korea, which have launched sprawling packages to provide the important components in the US, Australia, and Canada. The efforts are geared toward making certain a provide of crucial uncommon earths within the occasion that China—which produces

roughly 90 percent of processed, industry-ready uncommon earths—decides to limit their export. Now, after greater than a decade of effort, and after billions of {dollars} spent by personal firms in addition to the U.S. and different governments, 2025 will likely be a yr when some outcomes of all this cash and exercise ought to turn out to be conspicuous.

“The monitor file of success on this {industry} is abysmal.”

—Michael Rosenthal, cofounder, MP Supplies

MP Supplies, for instance, expects to extend manufacturing this yr of its neodymium praseodymium product, whereas additionally finishing a facility to provide completed, high-quality everlasting magnets close to Fort Value, Texas. In the meantime, MP’s solely massive competitor exterior of China,

Lynas Rare Earths of Perth, Australia, expects to start work on a mammoth uncommon earth–processing facility being in-built Seadrift, Texas with US $258 million from the U.S. Division of Protection (DOD).

However each bit as probably transformative as these massive, publicized tasks is one hardly identified in any respect, even throughout the small neighborhood of uncommon earth traders, builders, and researchers. This yr, researchers at Oak Ridge Nationwide Laboratory will function and analyze a pilot line based mostly on a brand new chemical-extraction methodology, invented by chemist

Santa Jansone-Popova. It seems able to decreasing the solvents, water, and vitality wanted to extract uncommon earths by as a lot as 60 % compared with the usual extraction course of. Such a technological advance might ultimately show indispensable for U.S., Australian, and different firms struggling to compete towards the Chinese language uncommon earth juggernaut, which operates scores of processing amenities, and is much less constrained by environmental rules.

The Uncommon Earths Enterprise Defies Categorization

There’s just about nothing simple concerning the uncommon earths {industry}. It’s a technology-based industrial endeavor upon which many different world, crucial, cutting-edge industries rely. It additionally occurs to be on the scorching nexus of geopolitics and protection. And it’s an {industry} with an traditionally checkered environmental file that’s now pivotal to a number of the largest and fastest-growing industries geared toward mitigating climate change.

The unease over China’s dominance of uncommon earth manufacturing spiked final December, when China introduced it will

begin banning the export to the US of sure crucial supplies. Notably, the ban doesn’t embrace uncommon earths, however the prohibition evoked a 2010 incident during which China quickly minimize all uncommon earth gross sales to Japan after a fishing dispute. Three years later, a report from the U.S. Congressional Analysis Service created a furor by mentioning that every F-35 Lightning II fighter jet contained 414 kilograms (about 920 kilos) of uncommon earth supplies.

Fairly quickly, the cash started gushing. It got here from U.S. companies, notably

the DOD, in addition to others in Japan and Korea and from personal traders. Scores of firms and ventures sprang up—eventually rely, more than 146 massive uncommon earth tasks have been underway, of which no less than 96 have been in North America, Australia, Europe, and South America.

In the US, most efforts concentrate on self sufficiency. However the highway from right here to there may be going to be fairly tough. “Making uncommon earths is actually, actually exhausting,” says Rosenthal. “It’s very costly, you want a variety of gear, and the monitor file of success on this {industry} is abysmal.”

So, not surprisingly, nearly all of these 146 massive uncommon earth tasks are mining ventures, not processing ones, they usually’ll do little or no to diversify the uncommon earth provide. “It’s vital that now we have a extra numerous provide chain, exterior of China, and an even bigger one,” agrees Rosenthal. “However the {industry} is poorly served by the quantity of hype and unjustifiable press relating to sources (exploratory mine websites) that aren’t effectively understood. What we actually want extra of is processing capabilities, from all elements of the availability chain.” A brand new uncommon earth mine, Rosenthal factors out, does nothing to extend the geographical range of provide if its output should go to China to be processed into uncommon earth oxides.

Neodymium-bearing uncommon earth compounds, akin to this neodymium praseodymium oxide powder produced by MP Supplies at its Mountain Move website, are of immense industrial, navy, and industrial significance.MP Supplies

In the present day, such preparations are frequent. China’s dominance of uncommon earth processing is such that even MP Supplies Corp., the mother or father firm that controls the Mountain Move mining and processing operations, sends a few of its ore to China for processing. And a Chinese language firm, Shenghe Assets Holding Co., owns roughly 7.7 % of the inventory of MP Supplies.

“China has constructed no less than 50 uncommon earth separation vegetation within the final 10 years,” Rosenthal estimates. For comparability, exterior of China, there are solely three separation amenities able to producing uncommon earth oxides at industrial scale. One is Mountain Move; one other is the Silmet manufacturing facility in Sillamäe, Estonia, which is owned by Toronto-based Neo Efficiency Supplies; and the third is the massive

Lynas advanced materials plant, close to Kuantan in Malaysia. (One other Lynas facility, in Kalgoorlie, Australia, produces a mix of uncommon earth carbonates that may be changed into industrially helpful oxides at buyer websites.)

Redistributing Refining

Refining uncommon earth ore into uncommon earth oxides begins with a course of referred to as

beneficiation within the {industry}. Right here, the rocks are first damaged down into chunks of gravel which can be then blended with water and crushed right into a slurry. Then, within the comparatively environmentally pleasant course of used at Mountain Move, referred to as froth flotation, a sort of chemical reagent referred to as a surfactant is added to the slurry. This combination is launched right into a sequence of vessels, or cells, during which the surfactants trigger the uncommon earth–bearing grains to bind selectively to bubbles floating to the highest of the cells. Because the bubbles float upwards, they carry the uncommon earth–bearing grains with them, separating them from the waste grains. After a number of phases, what’s left after drying is a positive powder referred to as uncommon earth focus. The purpose is for this focus to be no less than 60 % uncommon earth oxides by weight.

The following step known as leaching. At Mountain Move, the focus is roasted after which leached with hydrochloric acid to place the high-value uncommon earth components into answer. Many of the cerium, a low-value uncommon earth, is eliminated on this stage.

Baggage of neodymium praseodymium oxide powder, every containing one metric tonne of the compound, await delivery from a warehouse on the Mountain Move website in California.Michael Tessler/MP Supplies

Baggage of neodymium praseodymium oxide powder, every containing one metric tonne of the compound, await delivery from a warehouse on the Mountain Move website in California.Michael Tessler/MP Supplies

The following stage is essentially the most sophisticated and vital. Right here, the particular uncommon earth components being sought, for instance neodymium and praseodymium, are separated from the opposite uncommon earths. The usual method known as

solvent extraction, and it’s not a lot completely different from the method invented 70 years in the past by researchers at Argonne National Laboratory and Oak Ridge National Laboratory.

The strategy known as liquid-liquid as a result of it makes use of two immiscible solvents, one water- and the opposite oil-based. The uncommon earths are dissolved in one of many solvents, which is blended vigorously with the opposite one. To separate out particular uncommon earths, the method makes use of an natural extractant and exploits delicate variations within the affinity of that extractant for various uncommon earth components underneath explicit course of circumstances.

Right here’s the way it works. There’s a water-based, acidic answer containing the uncommon earths, which known as the aqueous section. It’s blended with an oil-based, or natural, section, consisting of that natural extractant and a diluent. Technicians alter the method circumstances, akin to temperature and stress, to permit the extractant to bind preferentially to the particular uncommon earth ions to be recovered, say neodymium. When the aqueous section and the natural section are blended vigorously, these neodymium ions bind to the extractant, which pulls them into the natural section. As a result of this oil-based section is just not miscible with the aqueous one, the neodymium ions are separated from the others. In observe, the vigorous combining happens in vessels referred to as mixers, after which the mixed liquids are pushed into an adjoining container referred to as a settler, the place the 2 phases slowly separate, with the goal uncommon earths accumulating within the natural section and the less-desired uncommon earths being scrubbed again into the aqueous section.

This mixing and settling occurs over and over. Every time the focus of the specified uncommon earths is elevated incrementally. After many iterations, the goal uncommon earths are then usually transferred again to the aqueous section. Then they’re recovered by the use of a precipitation method.

If all of it sounds fairly simple, it’s not. At Mountain Move, Rosenthal takes me into the constructing, bigger than a soccer subject, the place the extraction takes place. I’ve toured loads of imposing industrial and technological websites, however I’ve by no means seen something fairly like this. After my eyes alter to the dim gentle, I see columns of big, paired vessels, towering over me, off into the space. They’re every about 20 cubic meters (roughly 5,000 gallons), and there are no less than 100 of them (the precise quantity is a commerce secret, I’m informed). These are the mixers and settlers.

How Oak Ridge Reinvented Uncommon Earth Extraction

Correctly tuned, the liquid-liquid solvent-extraction course of will be extraordinarily efficient, producing uncommon earth oxides with purity larger than 99.9 %. But it surely has some substantial drawbacks. Within the course of, the natural section is a phosphate-based compound, akin to tributyl phosphate, and the aqueous section is a powerful acid, akin to hydrochloric, nitric, or sulfuric. These solvents and reagents are utilized in huge portions, which will be recycled however should all be disposed of ultimately.

Plenty of analysis now could be geared toward

identifying better extractants—for instance, ones that allow much less acidic processes or that chemically bind extra selectively with the specified uncommon earths. A measure of the effectiveness of an extractant is separation issue, which signifies how a lot of the goal uncommon earth factor is pulled from answer relative to adjoining uncommon earths as they undergo one spherical of mixer-settlers. For the traditional system right this moment, the separation elements of adjoining uncommon earths differ between 1.1 and about 6. For comparability, separation elements for different chemical-industrial processes can exceed 100.

“When you can double or triple the separation issue, then you possibly can halve or cut back the variety of mixer-settlers by as much as two-thirds,” says Tom Lograsso, director of a U.S. government-led consortium referred to as the

Critical Materials Innovation Hub, which is sponsoring analysis on the issue. “If there was a panacea to scale back the prices, the capital prices, the land utilization, the water utilization, and enhance the environmental soundness of the processing, it will be to provide you with chemical compounds which can be environmentally protected, and that may additionally do a greater job of separating the uncommon earths from one another.”

Analysis chemist Santa Jansone-Popova, at Oak Ridge Nationwide Laboratory, invented the DGA-6 chemical that would revolutionize uncommon earth extraction.Carlos Jones/ORNL/U.S. Division of Vitality

Analysis chemist Santa Jansone-Popova, at Oak Ridge Nationwide Laboratory, invented the DGA-6 chemical that would revolutionize uncommon earth extraction.Carlos Jones/ORNL/U.S. Division of Vitality

At Oak Ridge, the venture led by Jansone-Popova, with funding from the Important Supplies Innovation hub, is doing precisely that. Jansone-Popova notes that with the traditional course of, the options turn out to be extra acidic as they proceed by way of successive phases of mixer-settlers.

“As a way to recuperate these uncommon earth components in that oil-aqueous separation system,” she explains, “you must use extra concentrated aqueous answer—extra acidic answer,” she notes. That, in flip, she provides, requires the usage of alkali to decrease the acidity of that answer, in order that the aqueous stream will be recycled. “Which means including extra chemical compounds to the system, which isn’t preferrred, and which, on the finish, leads to producing extra waste, producing environmental issues,” she says.

Her answer? Use an extractant that doesn’t function based mostly on changes in acidity. “It operates by a unique mechanism, changes in ionic energy,” says Jansone-Popova. “Which means we are able to begin with a extra concentrated acid answer, after which we are able to recycle that acid answer with out including any chemical compounds. And after we wish to recuperate these uncommon earth components, we’re utilizing a really dilute acidic answer that, too, will be recycled after the precipitation of the uncommon earths. We will principally recuperate these uncommon earth components with water. There aren’t any further chemical compounds added to the system, and all of the acid that we’re utilizing within the course of will be recycled. That’s the wonder.”

And it’s not even

all the wonder. The brand new extractants are additionally way more selective, enhancing the separation issue by two to 3 instances compared with the prevailing processes.

A brand new high-efficiency course of for extracting particular uncommon earth components was pioneered at Oak Ridge Nationwide Laboratory. The method will depend on a chemical, diglycolamide-6 (DGA-6) [in beaker above] which is now being manufactured by Marshallton Analysis Labs.Carlos Jones/ORNL/U.S. Division of Vitality

A brand new high-efficiency course of for extracting particular uncommon earth components was pioneered at Oak Ridge Nationwide Laboratory. The method will depend on a chemical, diglycolamide-6 (DGA-6) [in beaker above] which is now being manufactured by Marshallton Analysis Labs.Carlos Jones/ORNL/U.S. Division of Vitality

The brand new extractant is from a chemical household referred to as diglycolamides, or DGAs. Jansone-Popova refers back to the one her group is at the moment creating as DGA-6. It’s used within the oil section, and one other new extractant, additionally developed by her group, is used within the aqueous section. “Our purpose is to do the movement sheet demonstrations and to persuade {industry} that this can be a higher course of,” she declares.

She already has one convert in {industry}. Mac Foster is co-owner of

Marshallton Research Laboratories, which offers chemical compounds for extraction processes within the nuclear and uncommon earth industries. He’s been collaborating with Jansone-Popova, and he likes what he sees. “In comparison with the state-of-the-art [traditional-process extractants], this new class of DGAs is way cleaner in its operation as a result of these extractants are impartial,” he says. “They’re not acids. In order that they don’t require massive swings involving neutralization of enormous quantities of acid. They’re extra environment friendly.”

Marshallton, which has a license to fabricate DGA-6, has been making comparatively small portions of it for analysis and testing at Oak Ridge. The corporate has additionally been offering recommendation on commercialization to Jansone-Popova’s group. “We have now improved the manufacturing course of for DGA-6,” Foster provides. “By that, I imply what we’re doing is just not within the literature. And it results in a decrease price to make the extractant. It’s higher suited to scaling up.”

Again at Mountain Move, I ask Rosenthal concerning the Oak Ridge work. He likes what he’s heard up to now. “If the Oak Ridge extractant is extra selective, we wouldn’t want as many tanks,” he notes.

Over the long term, Western uncommon earth producers are going to want one thing extraordinary to bolster their efforts to compete with their Chinese language counterparts—who’re additionally pursuing diglycolamides as

extractants for rare earth processing. If it isn’t the Oak Ridge course of it’ll should be one thing very very like it. And the earlier the higher.