This week on the IEEE Electronic Components and Packaging Technology Conference, Intel unveiled that it’s growing new chip packaging know-how that may permit for larger processors for AI.

With Moore’s Regulation slowing down, makers of superior GPUs and different information middle chips are having so as to add extra silicon space to their merchandise to maintain up with the relentless rise of AI’s computing wants. However the most dimension of a single silicon chip is fastened at round 800 sq. millimeters (with one exception), in order that they’ve needed to flip to advanced packaging technologies that combine a number of items of silicon in a manner that lets them act like a single chip.

Three of the improvements Intel unveiled at ECTC had been aimed toward tackling limitations in simply how a lot silicon you’ll be able to squeeze right into a single bundle and the way massive that bundle might be. They embrace enhancements to the know-how Intel makes use of to hyperlink adjoining silicon dies collectively, a extra correct methodology for bonding silicon to the bundle substrate, and system to broaden the scale of a essential a part of the bundle that take away warmth. Collectively, the applied sciences allow the mixing of greater than 10,000 sq. millimeters of silicon inside a bundle that may be larger than 21,000 mm2—an enormous space in regards to the dimension of 4 and a half credit cards.

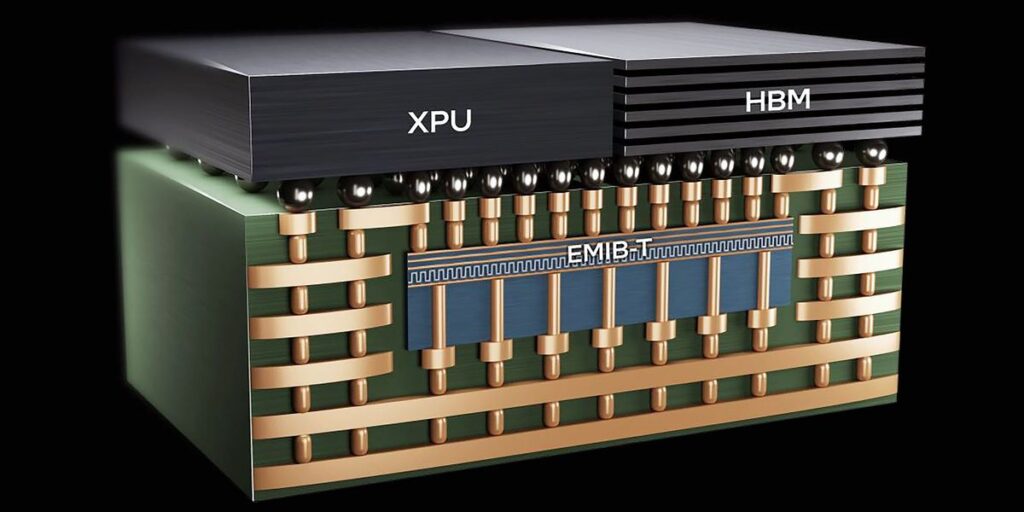

EMIB will get a 3D improve

One of many limitations on how a lot silicon can slot in a single bundle has to do with connecting numerous silicon dies at their edges. Utilizing an natural polymer bundle substrate to interconnect the silicon dies is probably the most reasonably priced possibility, however a silicon substrate permits you to make extra dense connections at these edges.

Intel’s resolution, launched greater than 5 years in the past, is to embed a small sliver of silicon within the natural bundle beneath the adjoining edges of the silicon dies. That sliver of silicon, referred to as EMIB, is etched with nice interconnects that improve the density of connections past what the natural substrate can deal with.

At ECTC, Intel unveiled the most recent twist on the EMIB know-how, referred to as EMIB-T. Along with the same old nice horizontal interconnects, EMIB-T offers comparatively thick vertical copper connections referred to as through-silicon vias, or TSVs. The TSVs permit energy from the circuit-board under to immediately hook up with the chips above as a substitute of getting to route across the EMIB, decreasing energy misplaced by an extended journey. Moreover, EMIB-T incorporates a copper grid that acts as a floor aircraft to cut back noise within the energy delivered on account of course of cores and different circuits all of a sudden ramping up their workloads.

“It sounds easy, however this can be a know-how that brings plenty of functionality to us,” says Rahul Manepalli, vp of substrate packaging know-how at Intel. With it and the opposite applied sciences Intel described, a buyer might join silicon equal to greater than 12 full dimension silicon dies—10,000 sq. millimeters of silicon—in a single bundle utilizing 38 or extra EMIB-T bridges.

Thermal management

One other know-how Intel reported at ECTC that helps improve the scale of packages is low-thermal-gradient thermal compression bonding. It’s a variant of the know-how used immediately to connect silicon dies to natural substrates. Micrometer-scale bumps of solder are positioned on the substrate the place they’ll hook up with a silicon die. The die is then heated and pressed onto the microbumps, melting them and connecting the bundle’s interconnects to the silicon’s.

As a result of the silicon and the substrate broaden at totally different charges when heated, engineers should restrict the inter-bump distance, or pitch. Moreover, the growth distinction makes it troublesome to reliably make very massive substrates stuffed with numerous silicon dies, which is the path AI processors must go.

The brand new Intel tech makes the thermal growth mismatch extra predictable and manageable, says Manepalli. The result’s that very-large substrates might be populated with dies. Alternatively, the identical know-how can be utilized to extend the density of connections to EMIB all the way down to about one each 25 micrometers.

A flatter warmth spreader

These larger silicon assemblages will generate much more warmth than immediately’s programs. So it’s essential that the warmth’s pathway out of the silicon isn’t obstructed. An built-in piece of steel referred to as a warmth spreader is vital to that, however making one large enough for these massive packages is troublesome. The bundle substrate can warp and the steel warmth spreader itself won’t keep completely flat; so it won’t contact the tops of the recent dies it’s imagined to be sucking the warmth from. Intel’s resolution was to assemble the built-in warmth spreader in elements as a substitute of as one piece. This allowed it so as to add further stiffening parts amongst different issues to maintain every little thing in flat and in place.

“Holding it flat at greater temperatures is an enormous profit for reliability and yield,” says Manepalli.

Intel says the applied sciences are nonetheless within the in R&D stage and wouldn’t touch upon when these applied sciences would debut commercially. Nonetheless, they’ll possible should arrive within the subsequent few years for the Intel Foundry to compete with TSMC’s planned packaging expansion.

From Your Website Articles

Associated Articles Across the Internet