This text is a part of our unique IEEE Journal Watch series in partnership with IEEE Xplore.

Two semiconductors—silicon carbide and gallium nitride—are the rivals in a (fairly actually) heated competitors to make circuits able to performing on the highest temperatures. Silicon carbide chips had taken the lead, working at 600 °C. However gallium nitride, which possesses distinctive options that make it extra purposeful at excessive temperatures, has now surpassed SiC. Researchers at Pennsylvania State College led by Rongming Chu, a professor of electrical engineering, have designed a gallium nitride chip able to operating at 800 °C —sizzling sufficient to soften desk salt.

The event could possibly be vital to future area probes, jet engines, pharmaceutical processes, and a bunch of different purposes that want circuits for excessive situations. Silicon carbide high-temperature chips have allowed scientists to place sensors in locations they weren’t in a position to earlier than, says Alan Mantooth, a professor {of electrical} engineering and pc science on the College of Arkansas, who was not concerned within the new gallium nitride consequence. He explains that the gallium nitride chip may do the identical in monitoring the well being of natural gas generators, energy-intensive manufacturing processes in chemical crops and refineries, and methods nobody has even considered but.

“We are able to put this sort of electronics in locations silicon merely can’t even think about going,” he says.

Each silicon carbide and gallium nitride’s potential to carry out below such excessive situations comes from their large bandgaps. These are the power gaps between the supplies’ valence bands, the place electrons are certain to the molecule, and the conduction band, the place they’re free to contribute to the move of electrical energy. At excessive temperatures, electrons in supplies with a narrower bandgap are all the time excited sufficient to achieve the conduction band. This presents an issue for transistors, as a result of they’ll then be unable to change off. The large bandgaps of silicon carbide and gallium nitride require extra power to excite electrons to the conduction band, in order that the transistors aren’t unintentionally all the time switched on in high-temperature environments.

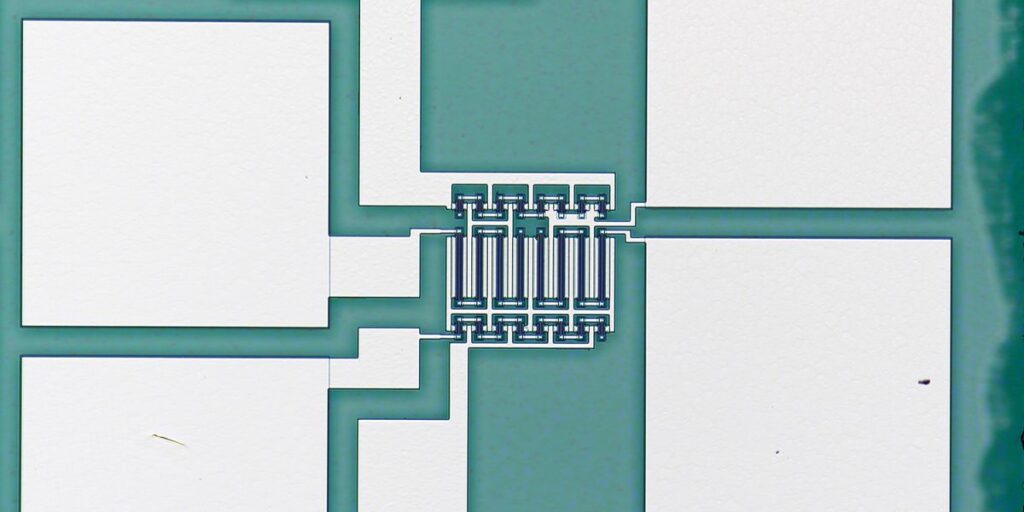

Gallium nitride additionally has distinctive options in comparison with silicon carbide which permit its chips to carry out higher below high-heat situations. Chu’s group’s IC, which they described this month in IEEE Electron Device Letters, consists of what are referred to as gallium nitride high electron mobility transistors (HEMT). The construction of GaN HEMTs includes an aluminum gallium nitride movie on high of a layer of gallium nitride. The construction attracts electrons to the interface between the 2 supplies.

This layer of electrons—referred to as a two-dimensional electron gas (2DEG)—is very concentrated and strikes with little resistance. This implies cost strikes a lot quicker within the 2DEG, main the transistor to have the ability to reply to adjustments in voltage and change between its on and off states extra shortly. Sooner electron motion additionally permits the transistor to hold extra present in response to a given voltage. The 2DEG is tougher to provide utilizing silicon carbide, making it harder for its chips to match the efficiency of gallium nitride units.

To coax a GaN HEMT into working at 800 °C took some alterations to its construction, explains Yixin Xiong, Chu’s graduate pupil. A few of these measures concerned minimizing leakage current, cost that sneaks throughout even when the transistor is meant to be off. They did this through the use of a tantalum silicide barrier to guard the gadget’s parts from the setting and by stopping the outer layer of the metallic on the edges of the gadget from touching the 2DEG, which might have additional elevated leakage present and instability within the transistor.

Penn State engineers examined excessive electron mobility transistors at 800 °C.Rongming Chu/Pennsylvania State College

Chu says that the analysis and fabrication strategy of the chip went a lot quicker than he had anticipated. The workforce had been assured that the experiment would work, he says. However it was “quicker than my greatest guess,” he says.

Regardless of the notable advantages it presents, Mantooth is worried about gallium nitride’s long-term reliability in comparison with silicon carbide. “One of many issues that individuals have been involved about with GaN at these excessive temperatures, 500 ℃ and above, is microfractures or microcracking [which is] not one thing that we’re essentially seeing in silicon carbide, so there could also be reliability points” with GaN, he explains.

Chu agrees that long-term reliability is an space for enchancment, saying “there are just a few technical enhancements we are able to make: One is making it extra dependable at a excessive temperature. Proper now, I feel we are able to maintain at 800 ℃ for most likely 1 hour.”

Gallium Nitride vs. Silicon Carbide

There’s nonetheless a number of work to be finished to enhance the gadget, says Xiong. He explains that apart from minimizing leakage present, one perform of the tantalum silicide barrier is to stop titanium within the gadget from doubtlessly reacting with the AlGaN movie, which may destroy the 2DEG. Ultimately, Xiong desires to take away titanium from the gadget altogether. “The last word purpose, I might say, is to not depend on titanium,” he concludes.

Regardless of its potential longevity challenges, the group’s chip is pushing the boundaries of the place electronics can function, corresponding to on the floor of Venus. “Should you can maintain it for 1 hour at 800 ℃, that signifies that at 600 or 700 ℃, you possibly can maintain it for for much longer,” Chu explains. Venus’s ambient temperature is 470 ℃, so GaN’s new temperature file could possibly be helpful for electronics in a Venus probe.

The 800 ℃ determine can also be necessary for hypersonic aircraft and weapons, explains Mantooth. Their excessive speeds generate friction that may warmth up the floor to 1,500 ℃ or extra. “One of many issues lots of people don’t understand is that once you’re flying at Mach 2, or Mach 3, the air friction creates an extreme environment on the forefront of the wing…. And guess what? That’s the place your radar is situated. That’s the place different processing tools is situated. These purposes are why the U.S. Protection Division is keen on electronics for excessive temperatures,” says Mantooth.

So far as plans for the longer term, Chu says the following steps are to “scale the gadget to make it run quicker.” He additionally thinks that the chip could also be prepared for commercialization not too far down the road, as a result of there are so few suppliers for chips able to working at such excessive temperatures. “I feel it’s fairly prepared. It requires some enhancements, however the good factor about high-temperature electronics is there’s nothing else there,” he says.

The gallium nitride circuit’s victory towards its silicon carbide companions might not final lengthy, nonetheless. Mantooth’s lab additionally fabricates high-temperature chips, and is engaged on getting silicon carbide to hit the warmth ranges that Chu’s chips have. “We’ll be fabricating circuitry to attempt to assault the identical temperatures with silicon carbide,” says Mantooth. Although it’s unclear who will ultimately end on high, not less than one factor is for certain: The competitors remains to be heating up.

From Your Web site Articles

Associated Articles Across the Net