Researchers on the Royal Melbourne Institute of Expertise simply invented a constructing materials that might make building tasks stronger and extra sustainable—and it’s primarily based on the skeleton of an invertebrate that lives on the backside of the ocean.

The fabric, recently presented in the journal Composite Structures, was developed by RMIT College engineers. It’s impressed by the skeleton of the deep-sea sponge, whose lattice-like inner buildings, which have been optimized over tens of millions of years within the ocean, permit it to thrive hundreds of ft underwater.

The fabric’s distinctive structural properties make it concurrently light-weight, sturdy, and further resilient underneath strain, that means that it might finally assist make buildings sturdier with much less metal and concrete.

How are metal and concrete damaging the surroundings?

For years, engineers have been researching new ways to cut down on steel and concrete in construction. That’s as a result of each supplies are produced at a large scale, with equally massive impacts on the environment.

As of 2023, annual global production of concrete was around a whopping 30 billion tons, and the manufacturing of cement—one in all concrete’s key elements—was accountable for between 5% and 10% of worldwide CO2 emissions. In the meantime, the steelmaking industry churns out about 2 billion tons of the metallic per yr, accounting for around 7% of greenhouse gas emissions.

Scientists have explored a variety of alternate options to conventional metal and concrete, together with a steel alternative made out of plastic and a form of concrete stabilized by recycled diapers.

Biomimicry as a foundation for design

The RMIT workforce’s sponge-inspired materials might assist scale back metal and concrete use in building due to one thing known as “auxetic habits.”

The phrase “auxetic” is a structural descriptor which implies that, as an alternative of turning into thinner when stretched and thicker when compressed, the fabric really turns into thicker when stretched and thinner when compressed. A honeycomb, for instance, is often auxetic, as are organic supplies like cat tongues and human muscle tendons. Within the manufacturing world, auxetic supplies are sometimes used on the underside of trainers, permitting the footwear to broaden whereas strolling or operating.

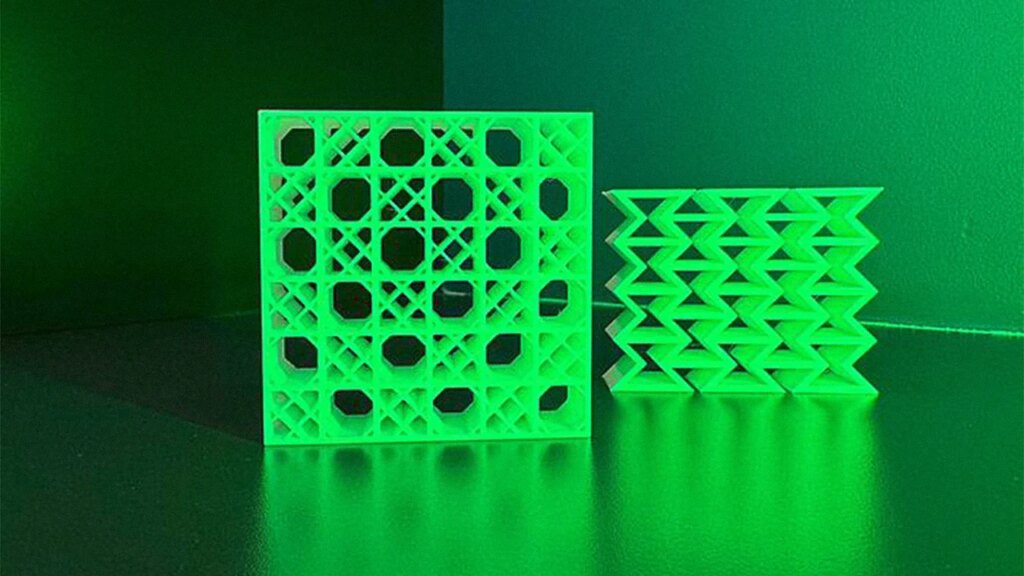

Auxetic patterns are fascinating in building as a result of they’ll take in pressure and preserve their energy underneath intense strain, similar to the deep-sea sponge. Current man-made auxetic supplies sometimes use a honeycomb sample, however RMIT’s new materials makes use of a double lattice design supported by diagonal beams. Based mostly on the workforce’s testing, the modern construction makes the fabric 13 instances stiffer than different fabricated auxetics.

For that reason, the brand new sample might be utilized in building to allow “thinner load-bearing partitions and slimmer columns with out compromising structural integrity,” in accordance with Jiaming Ma, the lead writer on the brand new examine. That may lower down on the quantity of metal and concrete vital to realize a sturdy consequence.

The fabric continues to be within the testing part, so it’s too early to foretell what wide-scale business use may seem like. Nonetheless, Ma believes it might finally have purposes throughout a variety of industries, from creating earthquake-resistant buildings to enhancing vascular stents and strengthening protecting sports activities gear.